المنتجات الساخنة

Iron Ore Crusher Mining, Crushing, Grinding, Beneficiation

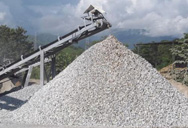

2011-10-15 Iron ore processing can be a procedure that contains explosions, shoveling, moving, crushing, grinding, pelletizing etc. Iron ore processing provides a range of coarse sizing that may produce material in 24-inch to .0017-inch particle sizes. In iron ore crushing and screening process is really a basic connect to concentrator will have an effect

Contact

Iron Ore Crusher Price, Crushing Machine for Iron Ore

2021-5-18 The iron ore crushers with low price are also used in the industrial minerals, mining, recycling and general quarrying industries. A widerange of materials are processed through mpl iron crushers worldwide. mpl experts can customize crushing solution in iron ore beneficiation according to your requirements. Here are some popular iron ore

Contact

Iron Ore Crusher, Iron Stone Crusher Machine, Iron Ore

2021-3-27 Jaw crushers. Jaw Crusher. Euro Jaw Crusher. 600 T/H Jaw Crusher. PE 500*750 Jaw Crusher. PE 1200*1500 Jaw Crusher. PE 250*400 Jaw Crusher. PE 600*900 Jaw Crusher. Sand makers. Primary crushing: You can use the iron ore jaw crusher for primary crushing. It is the most stable and reliable crushing equipment.

Contact

Iron Ore Processing,Crushing,Grinding Plant Machine

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation, flotation, and gravity separation, etc., iron is gradually selected from the natural iron ore.

Contact

Crushers an overview ScienceDirect Topics

Developments in iron ore comminution and classification technologies. A. Jankovic, in Iron Ore, 2015. 8.2.1. Crushers. Crushers are machines that use a rigid surface to compress and break large rocks into smaller rocks. They come in many varieties, and a summary of different crusher types is provided in Table 8.1.

Contact

Industries that Heavily Benefit from the Use of Crushers

2019-10-21 In the gathering of iron ore, big chunks of rock are often reduced to smaller pieces in order to specifically find the bits and pieces that contain the iron ore. Due to the worldwide demand and value of iron, crushers are used to process rock in an efficient and streamlined manner. That being said, when not using a crusher, dangerous and

Contact

Roller crushers in iron mining, how does the degradation

2021-4-1 Currently, in the mining process, roller crushers have been playing an important role due to their high productivity displayed in iron ore mining, as an example is an iron ore mine with friable hematite lithology and among others with uniaxial compression resistance of up to 200 MPa and Bond abrasiveness of up to 0, 37 g.

Contact

Rock Crusher Eastman Rock Crusher

Which hammer crusher can crush iron ore (100TPH)? In this case, we recommend the use of a PCZ1308 heavy hammer crusher with a feed size of 930x650mm, the feed particle size is less than 600mm, the motor power is 4P 132Kw, and the processing capacity of the equipment is 100-180t/h. Metallurgy area, use crushers and grinding mills for further

Contact

Crushers Mineral ProcessingMetallurgy

2016-10-23 The crusher weighed 225 tons and was belt- driven by a 250-B.HP. motor to give a speed of 23 r.p.m. to the crushing-roll. The feed-size reached a maximum of 4 feet by 7 feet and the crusher, when adjusted for a 7-inch product, gave an output of 700 tons per hour.

Contact

4 Types of Stone Crushers' Maintenance and Efficient

2021-10-28 4 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and minimize the downtime. 5 Clean your oil tank if it is contaminated. 6 Remove the fines or sticky material in the crushing chamber.

Contact

Iron Ore Crusher Machine Manufacturers and Iron Ore

2016-3-31 Mineral and mining industries use ore crushers to break down the material to evenly sized small granules or cubes as per the requirement. Ecoman, the most trusted partner for those firms working across the mining and mineral industries, has been serving the sector with exclusive range of iron ore crushers that are carefully designed and

Contact

Industries that Heavily Benefit from the Use of Crushers

2019-10-21 In the gathering of iron ore, big chunks of rock are often reduced to smaller pieces in order to specifically find the bits and pieces that contain the iron ore. Due to the worldwide demand and value of iron, crushers are used to process rock in an efficient and streamlined manner. That being said, when not using a crusher, dangerous and

Contact

Primary Crusher an overview ScienceDirect Topics

Developments in iron ore comminution and classification technologies. A. Jankovic, in Iron Ore, 2015. 8.2.1. Crushers. Crushers are machines that use a rigid surface to compress and break large rocks into smaller rocks. They come in many varieties, and a summary of different crusher types is provided in Table 8.1.

Contact

types of iron ore crushers e28093 in togo

2021-7-1 iron ore buyers, buying leads, iron ore importers ec21. Korea. Contact Now. We Buy Iron Ore HBI. 14 Dec, 2020. We drthshih at gmail+17133848091 are interested in buying Hot Briquetted Iron (HBI), 75% 86%, 100,000 MT/Month x12 with R&E Also need Iron Ore, Copper Ore, Copper Concentrate, zinc ore and lead ore

Contact

Extraction Of Iron Ore

2020-12-11 Economic Sustainability. With such a large reserve of iron ore, we export a large sum of it to other countries that need iron, which makes us money. According to Statistics Canada, In 2018, Canada had exported 3.4billion dollars of iron ore and concentrates. The iron ore production industry is relatively important for our GDP.

Contact

Rock Crusher Eastman Rock Crusher

Which hammer crusher can crush iron ore (100TPH)? In this case, we recommend the use of a PCZ1308 heavy hammer crusher with a feed size of 930x650mm, the feed particle size is less than 600mm, the motor power is 4P 132Kw, and the processing capacity of the equipment is 100-180t/h. Metallurgy area, use crushers and grinding mills for further

Contact

Crushers Mineral ProcessingMetallurgy

2016-10-23 The crusher weighed 225 tons and was belt- driven by a 250-B.HP. motor to give a speed of 23 r.p.m. to the crushing-roll. The feed-size reached a maximum of 4 feet by 7 feet and the crusher, when adjusted for a 7-inch product, gave an output of 700 tons per hour.

Contact

Type of crushers and their difference JXSC Mining

2019-12-10 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

Contact

4 Types of Stone Crushers' Maintenance and Efficient

2021-10-28 4 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and minimize the downtime. 5 Clean your oil tank if it is contaminated. 6 Remove the fines or sticky material in the crushing chamber.

Contact

Comminution and liberation response of iron ore types in

Introduction. Demand for iron ore is strongly dependent on the steel industry, since nearly 98% of it is used in steelmaking (USGS, 2019). After the boom in prices in the commodities, pulled by the growth in steel production in China, there was a strong drop in iron ore prices caused by a significant increase in supply of this commodity in the market, besides a reduction in its demand.

Contact

HOW DOES MINING EQUIPMENT WORK IN IRON ORE

2017-6-28 Represented on an iron ore flowchart, the crushers and grinders pair with magnetic rollers and other electronic separators. Other separation mechanisms in the process include wet and dry grinders, agitation tanks, and elevated vibrational screening decks. Iron ore mining shapes the world. The raw ferrous deposits are extracted and transformed

Contact

types of iron ore crushers e28093 in togo

2021-7-1 iron ore buyers, buying leads, iron ore importers ec21. Korea. Contact Now. We Buy Iron Ore HBI. 14 Dec, 2020. We drthshih at gmail+17133848091 are interested in buying Hot Briquetted Iron (HBI), 75% 86%, 100,000 MT/Month x12 with R&E Also need Iron Ore, Copper Ore, Copper Concentrate, zinc ore and lead ore

Contact

Metso makes assembled crushers attractive to iron ore

2010-11-10 Metso Minerals assembled crushers save time and improve safety for iron ore concentrator in Western Australia at the Karara project. This is an integrated development of a magnetite deposit, to produce both high grade magnetite concentrate on-site and blast furnace quality pellets in northeast China. Karara is a worldclassorebody in terms of

Contact

Rock Crusher Eastman Rock Crusher

Which hammer crusher can crush iron ore (100TPH)? In this case, we recommend the use of a PCZ1308 heavy hammer crusher with a feed size of 930x650mm, the feed particle size is less than 600mm, the motor power is 4P 132Kw, and the processing capacity of the equipment is 100-180t/h. Metallurgy area, use crushers and grinding mills for further

Contact

Crushers Mineral ProcessingMetallurgy

2016-10-23 The crusher weighed 225 tons and was belt- driven by a 250-B.HP. motor to give a speed of 23 r.p.m. to the crushing-roll. The feed-size reached a maximum of 4 feet by 7 feet and the crusher, when adjusted for a 7-inch product, gave an output of 700 tons per hour.

Contact

Iron ore mining and dressing tec-science

2018-6-21 Regions in which iron ore has formed over millions of years (e.g. through volcanism) and can be mined economically are also referred to as iron ore deposits. Especially many ore deposits can be found in countries such as China, Australia, Brazil, India and Russia. These countries account for around 85 % of the total global iron ore mining volume.

Contact

How Is The Iron Ore Mined? FTM Machinery

2019-4-19 Therefore, the mining of iron ore has been controlled by several large companies. Iron ore is the main component of steel and accounts for 95% of the world’s metal use each year. The world’s largest single iron ore producer is the Brazilian mining company called Vale, which produces more than 350 million tons of iron ore per year.

Contact

Type of crushers and their difference JXSC Mining

2019-12-10 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

Contact

4 Types of Stone Crushers' Maintenance and Efficient

2021-10-28 4 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and minimize the downtime. 5 Clean your oil tank if it is contaminated. 6 Remove the fines or sticky material in the crushing chamber.

Contact

Comminution and liberation response of iron ore types in

Introduction. Demand for iron ore is strongly dependent on the steel industry, since nearly 98% of it is used in steelmaking (USGS, 2019). After the boom in prices in the commodities, pulled by the growth in steel production in China, there was a strong drop in iron ore prices caused by a significant increase in supply of this commodity in the market, besides a reduction in its demand.

Contact