المنتجات الساخنة

Mining and Refining Water Management

Water is used to produce the steam required in the digestion process; in the preparation of aqueous caustic soda, flocculants and lime; to wash the ore, residues and recycled caustic and for dust mitigation. There are also uses such as vehicle washing, sanitation and provision of drinking water which occur at a refinery. The amount of water

Contact

Mining and Refining 水资源管理

Mining and Refining 水资源管理. 国际铝协(IAI)收集相关数据,以跟踪铝行业对水资源的影响,这些数据包括淡水用量和消耗量,以及水源强度指标。. 未来之铝 (Aluminum for Future Generation) 项目的目的在于:. IAI成员企业将致力于减少吨氧化铝所需的水消耗量

Contact

Refinery Water and Wastewater Treatment and Management

2021-3-31 Equally important in the management of water is to understand the major locations where water leaves the refinery: wastewater, steam losses, and cooling tower losses. Refineries can generate a significant volume of wastewater that has been in contact with hydrocarbons. Wastewater can also consist of rejected streams from boiler water processes

Contact

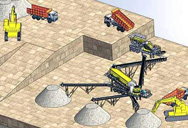

Mining and Refining Process World Aluminium

Mining and Refining Process. The Bayer Process was invented and patented in 1887 by Austrian scientist Karl Josef Bayer. Two to three tonnes of bauxite are required to produce one tonne of alumina. 90% of the global alumina supply of around 90 million tonnes is used in aluminium production. Alumina refineries tend to be located close to

Contact

New Approaches in Refinery Energy/Water Management

2017-8-8 The Davis Refinery will be equipped with the latest water treatment technology to reduce the amount of disposal waste water with the goal to become a zero-discharge facility. Air-cooled equipment will be installed to reduce the amount of water needed to be used throughout the facility. According to a research report produced early last year by

Contact

Understanding Mining Waste Management and Disposal

2020-5-21 Carefully monitor water at mine sites and devise mine water management strategies to reduce the amount generated. This water must be treated before it is released into the environment. Grinding and adding water and chemicals is a typical step of processing ores in the ore treatment refining plant. A large portion of the waste leaves the

Contact

Mining and Water Pollution — Safe Drinking Water

2016-12-17 3. Processing Chemicals Pollution. This kind of pollution occurs when chemical agents (such as cyanide or sulphuric acid used by mining companies to separate the target mineral from the ore) spill, leak, or leach from the mine site into nearby water bodies. These chemicals can be highly toxic to humans and wildlife. 4.

Contact

ITP Mining: Water Use in Industries of the Future: Mining

2012-11-14 Mining, Processing, a nd Conveyance Water use in mining operations can be divided into three categories: mining, processing, and mineral conveyance. In most types of mining, relatively little water is used in actual ore pro duction. A notable exception is underground coal mining, where water is used as one of sev eral measures to reduce the

Contact

Environmental Impact of Mining and Mineral Processing:

2022-5-6 The volume of water withdrawn by mining operations across the globe was approximately 20.1 million m 3 per day in 2010 (Jain et al., 2016) with the ABS (2016) recording that mining in Australia

Contact

Mine Water and the Environment Home Springer

2022-5-6 Founded in 1981 (as the International Journal of Mine Water), Mine Water and the Environment presents original contributions addressing technical questions and practical issues related to the evaluation, prediction, prevention, or control of water problems at mining operations or their impact on the environment. Both the journal and its audience are interdisciplinary.

Contact

Refinery Water and Wastewater Treatment and Management

2021-3-31 Equally important in the management of water is to understand the major locations where water leaves the refinery: wastewater, steam losses, and cooling tower losses. Refineries can generate a significant volume of wastewater that has been in contact with hydrocarbons. Wastewater can also consist of rejected streams from boiler water processes

Contact

Water management challenges at the world`s largest

1996-8-1 The U.S. Department of Energy's Office of Scientific and Technical Information

Contact

New Approaches in Refinery Energy/Water Management

2017-8-8 The Davis Refinery will be equipped with the latest water treatment technology to reduce the amount of disposal waste water with the goal to become a zero-discharge facility. Air-cooled equipment will be installed to reduce the amount of water needed to be used throughout the facility. According to a research report produced early last year by

Contact

MiningRefining Norbar

Hydraulic Ram Benches. Keeping hydraulic equipment maintained in good working order is fundamental to the smooth running of any mine site. PneuTorque® pneumatic wrenches have proved outstanding in the application of releasing and re-tightening the gland nut on the rod assembly of hydraulic cylinders. On the largest equipment, the gland nut release torque is

Contact

ITP Mining: Water Use in Industries of the Future: Mining

2012-11-14 Mining, Processing, a nd Conveyance Water use in mining operations can be divided into three categories: mining, processing, and mineral conveyance. In most types of mining, relatively little water is used in actual ore pro duction. A notable exception is underground coal mining, where water is used as one of sev eral measures to reduce the

Contact

Mining And Refining: Pure Silicon And The Incredible

2021-11-15 Polycrystalline silicon made by the Siemens process can have a purity of 99.99999% (“seven nines”, or 7N) or more. 7N to 10N polysilicon is mostly used for photovoltaic cells, although some

Contact

Environmental improvement of lead refining: a case study

2019-1-6 The lead industry is one of the top 10 water-consuming industries in China and suffers from the heavy burden of properly managing discharged wastewater containing heavy metals and organic pollutants. Accordingly, a water footprint analysis of lead refining was conducted in this study to enhance the water management in China’s lead industry.

Contact

Alumina Limited

Water forms an essential raw material, used at every point of AWAC’s mining, refining and smelting operations such as: bauxite ore refining into alumina ; dust suppression, road watering and vehicle and equipment cleaning throughout mining operations; ingot-casting process during smelting. AWAC’s management of water resources is vital to its:

Contact

Mine Water and the Environment Home Springer

2022-5-6 Founded in 1981 (as the International Journal of Mine Water), Mine Water and the Environment presents original contributions addressing technical questions and practical issues related to the evaluation, prediction, prevention, or control of water problems at mining operations or their impact on the environment. Both the journal and its audience are interdisciplinary.

Contact

Environmental Risks of Mining

2012-12-11 Environmental hazards are present during every step of the open-pit mining process. Hardrock mining exposes rock that has lain unexposed for geological eras. When crushed, these rocks expose radioactive elements, asbestos-like minerals, and metallic dust. During separation, residual rock slurries, which are mixtures of pulverized rock and

Contact

ITP Mining: Water Use in Industries of the Future: Mining

2012-11-14 Mining, Processing, a nd Conveyance Water use in mining operations can be divided into three categories: mining, processing, and mineral conveyance. In most types of mining, relatively little water is used in actual ore pro duction. A notable exception is underground coal mining, where water is used as one of sev eral measures to reduce the

Contact

Mining And Refining: Pure Silicon And The Incredible

2021-11-15 Polycrystalline silicon made by the Siemens process can have a purity of 99.99999% (“seven nines”, or 7N) or more. 7N to 10N polysilicon is mostly used for photovoltaic cells, although some

Contact

Mineral processing and refining ABB

The copper mining and processing industry requires large capital investments due to the remote locations, that requires additional infrastructure expenditure to meet the power and water demands. ABB has a long experience in helping many customers reduce capital and operational expenditure by optimizing electrical and automation system designs

Contact

Lithium Extraction and Refining Systems Saltworks

2018-6-8 Saltworks brings water mining expertise and advanced desalination technologies to our lithium clients, offering solutions for concentrating, refining, and converting low-grade lithium sources to battery-grade products. We offer processing technologies for higher purity, lower energy, boosting yield, removing unit operations, and reducing cost.

Contact

Evidence of the impacts of metal mining and the

2019-2-21 Mining activities, including prospecting, exploration, construction, operation, maintenance, expansion, abandonment, decommissioning and repurposing of a mine can impact social and environmental systems in a range of positive and negative, and direct and indirect ways. Mining can yield a range of benefits to societies, but it may also cause conflict, not least

Contact

Mine Water and the Environment Home Springer

2022-5-6 Founded in 1981 (as the International Journal of Mine Water), Mine Water and the Environment presents original contributions addressing technical questions and practical issues related to the evaluation, prediction, prevention, or control of water problems at mining operations or their impact on the environment. Both the journal and its audience are interdisciplinary.

Contact

Crimar Mining Mineral processing Smelting and

Mining Mineral processing Smelting and Refining Cement plants Power plants Water treatment Marine applications. Solids/liquids separation solvent extraction, municipal waste water, thickening thickeners, covers, filtration, hydro cyclones, collection systems

Contact

How to generate value from tailings with reprocessing to

2019-10-15 A standard method of reprocessing involves dragging tailings from an existing dam back to the concentrator and using required mineral processing solutions to liberate the valuable metals. The discarded tailings are then dewatered and dry stacked, and the water recycled within the plant or properly disposed back to nature.

Contact

The Potential Negative Effects Of Mining On The

2018-9-28 Environmentally, potential negative effects of mining can include air, land/soil and water pollution of different kinds. Mining produces potentially hazardous/toxic tailing waste, and can leach toxic chemicals, heavy metals and air pollutants. This can lead to air pollution via air contaminants, release of greenhouse gases like methane and CO2

Contact

SBCCO-China Mining Mineral processing Smelting

SBCCO-China is a majority foreign-owned Chinese corporation, originally set up to act as the purchasing office of Crimar Industrial, a US company that has been providing high quality industrial equipment to mining, smelting, water treatment, petrochemical, power and other industrial applications through its sales and support teams around the world.

Contact