المنتجات الساخنة

mining gold mill condition monitoring vibration

2016-6-7 Machine-Condition Monitoring using Vibration Analysis A Case Study from an Iron-Ore Mine by D.N.BrownJ.C.Jorgensen BriielKjeer Introduction Within the mining

Contact

Mining Gold Mill Condition Monitoring Vibration

Nov 18, 2018 Project background. A West Perth-based mining company engaged ESI Tech Group to implement a conditioning monitoring programme. Solution. ESI Tech Group worked

Contact

mining gold mill condition monitoring vibration

Condition Monitoring. Wireless Vibration Solution; Customer Success Story Gold Mine Mill Optimizer. A large gold mine in North America, was constrained by its ability to increase gold

Contact

Mining Gold Mill Condition Monitoring Vibration

Vibration monitoring system and the new methods of chatter early diagnostics for . Abstract Real time vibration monitoring and diagnostics system is developed and supplied for the 5

Contact

Mining Gold Mill Condition Monitoring Vibration

Nov 18, 2018 Project background. A West Perth-based mining company engaged ESI Tech Group to implement a conditioning monitoring programme. Solution. ESI Tech Group worked with the client to develop a schedule which involved regular visits to the site to monitor 200 items of rotating equipment, including the SAG and BALL MILLS, using our vibration analysis

Contact

mining gold mill condition monitoring vibration

2016-6-7 Machine-Condition Monitoring using Vibration Analysis A Case Study from an Iron-Ore Mine by D.N.BrownJ.C.Jorgensen BriielKjeer Introduction Within the mining industry an in- in a number of the vital phases of the fully used to detect and diagnose creasing trend in equipment design to- mining operation, with some impres- faults

Contact

mining gold mill condition monitoring vibration

vibration grinding roll. MVS Condition monitoring Machinery Vibration Specialists,Gold Grinder Grinding Mill Mine,Mining Plant Crusher Mill Project ©2009 ZENITH All Rights.

Contact

mining gold mill condition monitoring vibration

Condition Monitoring. Wireless Vibration Solution; Customer Success Story Gold Mine Mill Optimizer. A large gold mine in North America, was constrained by its ability to increase gold recovery. Operations were constrained by its ability to increase throughput in the grinding mill circuits due to several assets being in single line of failure

Contact

mining gold mill condition monitoring vibration

Reliability Technician, condition monitoring. Newmont Mining Corporation. Mar 2009 Jan 20133 years 11 months. Boddington gold mine. Development or the vibration database, work strategy development for condition monitoring and lubrication department, work procedure construction for lubrication department to OEM standards, supervision of 6

Contact

mining gold mill condition monitoring vibration

Vibration And Temparate Montoring In Ball Mill. Vibration And Temparate Montoring In Ball Mill. Ball mill vibration monitoring ball mills are a lowspeed application typical rotational speed is 1020 rpm where bearing damage can be challenging to detect condition monitoring of the ball mill began in december 2016 and right from the start the readings indicated potential damage

Contact

mining gold mill condition monitoring vibration

39 Condition Monitoring Vibration jobs in United States (1 new),New Condition Monitoring Vibration jobs added daily. The Nevada Gold Mines (NGM) TS Power Plant is looking for a Power Plant Reliability Engineer to join Noise and Vibration Supplemental Environmental BLM ePlanning,May 28, 2019 Reduced Mine Plan Alternative .

Contact

Mill Vibration Phenomena during Cold Rolling Innoval Technology

The simplest type of mill vibration is found in all mills. It is a forced vibration due to roll eccentricity and so occurs at roll rotation frequencies. These frequencies are usually lower than any of the resonant frequencies of the mill stand. Therefore, gauge variation is a result of the stiffness response of the mill and the material on the

Contact

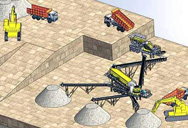

Condition Monitoring of Critical Mining Conveyors Emerson

Conveyors can replace haul trucks for delivering ore to the process plant in certain instances, but a breakdown can bring produ ction to a halt. Condition monitoring is essen-tial to keep operations functioning smoothly. Reprinted with Permission from E&MJ Condition Monitoring EMJ_3-15_Condition Monitoring EMJ_3-15 4/22/15 10:38 AM Page 51

Contact

Condition Monitoring of Ball Mill. AMP Maintenance Forums

May 16, 20083.For alarm limits, pl. refer Machine Dynamics August 1989 issue for bearing cap measurements.Also you may refer TSA limits of vibration in different frequency renages.. Also use high sensitivity(500 mv/g or above) accelerometers for measurement of slow speed vibration to distinguish signals from noise.

Contact

Mining Gold Mill Condition Monitoring Vibration

Vibration monitoring system and the new methods of chatter early diagnostics for . Abstract Real time vibration monitoring and diagnostics system is developed and supplied for the 5 stand 4 h tandem cold rolling mill 2022 NLMC Mechanism of chatter . gold mining equipement Mining Machinesgold mining equipement power fit australia vibration Gumtree Australia In the

Contact

Condition Monitoring of Critical Mining Conveyors EMJ

Conveyor systems, integral to operations, require conditioning monitoring to ensure uptime. Conveyors can replace haul trucks for delivering ore to the process plant in certain instances, but a breakdown can bring production to a halt. Condition monitoring is essential to keep operations functioning smoothly. Increasing reliability and lowering

Contact

mining gold mill condition monitoring vibration

vibration grinding roll. MVS Condition monitoring Machinery Vibration Specialists,Gold Grinder Grinding Mill Mine,Mining Plant Crusher Mill Project ©2009 ZENITH All Rights.

Contact

Mining Gold Mill Condition Monitoring Vibration

Condition Monitoring Of Ball Mill With Hd Technologies. Image 1 The ball mill at Orcem Netherlands Image 2 The gearbox just renovated with the shock pulse and vibration sensors Image 3 A principal overview of the ball mill 4 System setup 4 1 Measuring equipment Besides the gearbox the electric motor and the support bearings of the girth wheel are equipped with

Contact

mining gold mill condition monitoring vibration

2021-4-19 Middle Island Resources has determined it needs to conduct a mill upgrade at the Sandstone gold project in Western Australia otherwise the redevelopment of the site would not be viable. ; Condition Monitoring Alignment Semi-Online Vibration . Aimil offers wide range of laser alignment system and condition monitoring services.

Contact

Mining Gold Mill Condition Monitoring Vibration New Zealand

Mining Gold Mill Condition Monitoring Vibration New Zealand. Oversaw doubling in production rates following transition from 3 million tpa trucking mine to 65 million tpa hoisting mine implemented programs to monitor and validate drill and blast performance including drawpoint inspection programs fragmentation analysis blast vibration monitoring vod testing

Contact

mining gold mill condition monitoring vibration

Condition monitoring involves the regular measurement of parameters such as vibration, temperature and sound in and around machines and equipment. artisanal and small scale gold mining and gold ore crusher; 100tph ball mill and sand washer for quarry and mining;

Contact

mining gold mill condition monitoring vibration

Jul 05, 2016mineral processing condition monitoring of vibratory. Sample Processing Vibrating Machinery,Food/bead Rolling Sample Processing Vibrating Machinery,Food/bead Rolling Vibration Mixer Mill Crusher EnergyMineral Equipment >; Mining Machinery >; Mine Mill You can get different size powder by choosing the appropriate screen of Sciences,

Contact

Mining the potential of vibration monitoring Hansford Sensors

Jan 06, 2021Monitoring vibration, using vibration sensors fitted to equipment such as crushers, pumping systems, vibrating screens, load-out facilities and truck fleets, enables site engineers and maintenance teams to repair or replace components before failure occurs. The benefits of this can’t be underestimated. In fact, the total cost of unscheduled

Contact

mining gold mill condition monitoring vibration

Dec 26, 2020Choosing vibration monitoring methods Applications. Eventually it was decided to convert this offline-based data collection method to an online condition-monitoring concept.To evaluate the new system, three accelerometers were installed on the machine train, along with an RPM sensor, so the mine could compare vibration amplitudes to the actual RPM.

Contact

Vibration Based Condition Monitoring ofRolling Mill IJSER

Vibration Based Condition Monitoring of Rolling Mill V inod D.TIrpude, Jayant P.Modak, Girish D. Mehta Abstract: All over the India, most of the processing industries are involved with rolling operations for steel and alloyed materials. To

Contact

Condition Monitoring of Critical Mining Conveyors Emerson

Conveyors can replace haul trucks for delivering ore to the process plant in certain instances, but a breakdown can bring produ ction to a halt. Condition monitoring is essen-tial to keep operations functioning smoothly. Reprinted with Permission from E&MJ Condition Monitoring EMJ_3-15_Condition Monitoring EMJ_3-15 4/22/15 10:38 AM Page 51

Contact

Mining Gold Mill Condition Monitoring Vibration Tanzania

Mining Gold Mill Condition Monitoring Vibration Tanzania. What Are Measures To Prevent The Failures Of A Ball Mill Failure Gradual Wear Fracture And Temperature Failures Are Premature Failures Gradual Wear Is Preferred Because It Leads To The Longest Possible Use Of The Tool Gradual Wear Occurs At Two Locations On A Tool Crater Wear Occurs On Top

Contact

Vibration Monitoring: A Case Study Maintenance and

Jan 01, 2014Vibration-based condition monitoring (VCM) has over the years enjoyed a very significant level of popularity, due to its versatility and ability to promptly detect the least of changes in machine operation which could lead to eventual downtime. Coal mill main drive assembly, bag house fans and booster fans As shown in Tables 1-4, the fault

Contact