المنتجات الساخنة

Gyratory Crusher l Introduce, Working Principle JXSC Mine

Crusher Working Principle The primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall. In case of too hard or can not be broken, the roller crusher by hydraulic cylinder or the role of the spring can automatically retreat.

Contact

Gyratory Crusher an overview ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening.

Contact

basic principle of gyratory crusher

Jaw crusher is a main type of rock crusher used to crush minerals or stones into smaller sizes. It is an essential machine in a wide range of fields such as mining, quarrying and construction industries. Jaw crushers are usually used together with cone crushers, impact crushers and sand making machines to form a sandstone production line.

Contact

Working Principle of Crushers Mineral Processing

Feb 17, 2016Gyratory crushers work on a similar principle to jaw crushers but have a circular gap. Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axis. These are generally designed for primary crushing in large-scale rock crushing applications up to 6000 t/h.

Contact

Gyratory Crushers Mineral ProcessingMetallurgy

Feb 17, 2016Gyratory crusher advanced design includes the placing of circumferential ribs around the top and bottom shells. These integrally cast reinforcing rings prevent distortion provide the rigidity necessary to maintain true alignment of running parts. 30-55 MAINSHAFT ASSEMBLY ready for shipment SPIDER DESIGNED FOR MAXIMUM RIGIDITY AND STABILITY

Contact

Gyratory Crusher Explained saVRee

A primary crusher is designed to receive run-on-mine (ROM) rocks directly from the mines. Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory crushers are always installed vertically orientated. A gyratory crusher’s size is classified by: Its gape and mantle diameter.

Contact

Gyratory Crusher Mining Fundamentals

A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat, that is fixed. In mining, the most important criteria for effective crushing of ores is to choose the type of crusher that suits the rock (ore) material, and to ensure uniform feed.

Contact

Gyratory Crusher Animation YouTube

Aug 01, 2016The basic principle of how does a gyratory crusher work using an animation. https://911metallurgist/equipment/crushing/

Contact

Crusher Working Principle YouTube

Feb 17, 2016Describes the basic principle as to how a Gyratory or Jaw Crusher work at crushing rocks. More at https://911metallurgist/equipment/crushing/

Contact

Construction, Working and Maintenance of Crushers

Gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). The feed material should be at least 15 to 20% smaller than the width of the feed opening. Gyratory crusher’s discharge setting is referred to as the Open Side Setting (OSS).

Contact

Gyratory Crushers SolidsWiki

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardness.Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil

Contact

gyratory crusher work and principles Prominer Mining

Working Principle of Crushers. 2016-2-17 Gyratory crushers work on a similar principle to jaw crushers but have a circular gap. Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axis. These are generally designed for primary crushing in large-scale rock crushing More

Contact

Gyratory Crushers Dan Prinsip

Crusher Prinsip Gyratory Working Principle of Crushers View Larger Image On left is a showing of the standard gyratory with straight concaves is a section through any vertical radial plane in the crushing chamber of one of the intermediate sizes of the crusher Jaw Crusher.

Contact

Industrial Solutions Gyratory crushers ThyssenKrupp

Jaw gyratory crushers design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

Contact

worand principle of gyratory crusher

Aug 21, 2019Gyratory crusher working principle pdf The working principle of the crushers on the left is an exhibition of the "Standard Shrine with straight concaves" is a section through any vertical plane, radial in the crushing chamber of one of the intermediate dimensions of the crusher. to understand the overwhelming action in such a room it is useful

Contact

Gyratory Crusher Parts Wear Parts For Industry Qiming Casting

Working principle. The gyratory crusher is composed of transmission, frame, eccentric sleeve, mantle, concave segments, middle frame, beam, prime mover, oil cylinder, hydraulic pressure, pulley, electrical and dry, thin oil lubrication, and other parts. The motor drives the eccentric sleeve to rotate through the belt pulley and the bevel gear

Contact

Operating Principle Of Gyratory Crusher In Alaska

Apr 22 2013 crushers gyratory crusher working principle of gyratory crusher neyrtec gyratory crusher operation concrete crushersjaw sbm mining machinery is a professional material processing designer and supplier in the world we have excellent research and development group to provide our clients. learn more

Contact

gyratory crusher working

Gyratory crusher working principle,rock gyratory crushing plant saleyratory crushers have a continuous crushing capability and it leads to a higher throughput capacity compared to other High-Speed Gyratory Crushing --> Fine Cone Crushers.

Contact

gyratory crusher working kleemann crusher fault codes

Since the late 1800s, the size of crushers has greatly increased, but the engineering principles that make them work have remained the same. Gyratory crusher definition and meaning. The moving element of the gyratory crusher is a rotating crusher head and mantle on a vertical shaft. A gyratory crusher is a crusher in which a cone-shaped rod

Contact

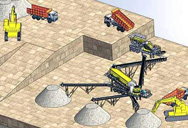

Construction, Working and Maintenance of Crushers for

Gyratory Crushers Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength.

Contact

Hammer Crusher Working Principle AGICO Cement Plant

The working principle of hammer crusher. Hammer crusher mainly breaks materials by the impact of hammers. The material entered into the working area of the crusher is crushed by high-speed hammers. The crushed material obtains kinetic energy from the hammers, and then it impacts on the crushing plate and grate screen at high speed and is broken

Contact

Cone Crusher Principle Of Operation Crushing Equipment

Aug 15 cone crusher and gyratory crusher work on the same principle both have the same operation if cone crusher differs then it is only from crushing chamber cone crusher has a less steep crushing chamber and more parallel zone between crushing zones it breaks the rocks by squeezing it between the gyrating.

Contact

Superior™ MKIII Series primary gyratory crushers Metso Outotec

Superior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development. The improvements to the Metso Outotec Outotec Superior™ MKIII crushers brings up to 70% reduction in downtime. Crusher maintenance downtime has also produced a significant size

Contact

Roll Crusher Working Principle Henan Deya Machinery Co., Ltd.

Jul 30, 2012Double roll crusher working principle. Roll crushers, or crushing rolls, or double roll crushers, are still used in some mills, although they have been replaced in most installations by cone crushers. They still have a useful application in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsum

Contact

worand principle of gyratory crusher

Aug 21, 2019Gyratory crusher working principle pdf The working principle of the crushers on the left is an exhibition of the "Standard Shrine with straight concaves" is a section through any vertical plane, radial in the crushing chamber of one of the intermediate dimensions of the crusher. to understand the overwhelming action in such a room it is useful

Contact

gyratory crusher work and principles Prominer Mining

Working Principle of Crushers. 2016-2-17 Gyratory crushers work on a similar principle to jaw crushers but have a circular gap. Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axis. These are generally designed for primary crushing in large-scale rock crushing More

Contact

principle of gyratory crusher

principles of operation in gyratory crushers Surya Range. principles of operation in gyratory crushers. Operation Principles Crushers Jaw crusher operation principle jaw crusher operation principle ivy camelway machinery the jaw crusher is the main component of the crushing plant it incorporates an electrical motor to dive a rotating shaft that throws the stones

Contact

gyratory gyratory crusher principle

Gyratory crushers work on the same principle as cone crushers (Figure 4.4(c)). These have a gyratory motion driven by an eccentric wheel. These machines will not accept materials with a large particle size and therefore only jaw or impact crushers should be considered as primary crushers. Gyratory and cone crushers are likely to become jammed

Contact

Principle Of Gyratory Crusher Indrostiz

the work principle of gyratory crusher the working principles of a gyratory crusher. cone 600 tph crushing plant with model,cone crusher working principle in ethiopia,600 tph mobile the working principle of gyratory crusher nicole008py.

Contact

Operating Principle Of Gyratory Crusher In Alaska

Apr 22 2013 crushers gyratory crusher working principle of gyratory crusher neyrtec gyratory crusher operation concrete crushersjaw sbm mining machinery is a professional material processing designer and supplier in the world we have excellent research and development group to provide our clients. learn more

Contact

gyratory crusher working kleemann crusher fault codes

Since the late 1800s, the size of crushers has greatly increased, but the engineering principles that make them work have remained the same. Gyratory crusher definition and meaning. The moving element of the gyratory crusher is a rotating crusher head and mantle on a vertical shaft. A gyratory crusher is a crusher in which a cone-shaped rod

Contact

gyratory crusher working

Gyratory crusher working principle,rock gyratory crushing plant saleyratory crushers have a continuous crushing capability and it leads to a higher throughput capacity compared to other High-Speed Gyratory Crushing --> Fine Cone Crushers.

Contact

gyratory crusher working mm max feeding jaw crusher

Gyratory Crusher l Introduce Working Principle JXSC Mine. Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has Gyratory Crusher. PERFORMANCE. why choose our Gyratory crusher: Efficient and Intelligent Production. High Output Yet, Low Crushing Costs.

Contact

Jaw Crusher Working Principle Gravel Mill

Jaw Crusher Working Principle. Jaw crusher is widely used in industrial and mining enterprises,this is because the aircraft structure is relatively simple,and has a large range of models . Jaw crusher is mainly used as the primary crusher. It can be used with mineral processing equipment,gravel ancillary equipment, it also can be used alone.

Contact

Jaw Crusher VS Gyratory Crusher JXSCMACHINE

Apr 20, 2019Gyratory crusher can work continuously, has high productivity and crushing ratio( up to 6-9.5), working performance is very stable, light vibration. Jaw crusher cannot work continuously, leading to lower productivity. Because of the working principle of squeeze crushing, the liner steel plate of the jaw crusher is easy to wear.

Contact

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

There are two kinds of. equipments used for crushing work s. one is by using crushers and other one is by using impacto rs. This diagram illustrates the stages of

Contact

Cone Crusher Principle Of Operation Crushing Equipment

Aug 15 cone crusher and gyratory crusher work on the same principle both have the same operation if cone crusher differs then it is only from crushing chamber cone crusher has a less steep crushing chamber and more parallel zone between crushing zones it breaks the rocks by squeezing it between the gyrating.

Contact

Crusher Principle Of Operation Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory Crusher Working Principle Mining equipment for This page is about gyratory crusher crushing principle, working principle, a patent on the For example, at the huge Homestake operation in 1915 there were o less than

Contact