المنتجات الساخنة

Aggregate Production Process Cornerstone Aggregates Inc.

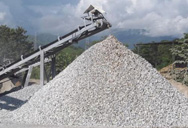

QUARRYING This is an essentials stage in the production process, because the quality of the aggregates produced depends on it. This is our consideration when we applied for our concession. The choice and selection of the source on the basis of its physical properties are decisions of strategic importance. HAULING

Contact

Stone Aggregate Plant Process

building stone making plant process cement aggregate with. Key points. • 'Aggregate' is a term for any particulate material. It includes gravel, crushed stone, sand, slag, recycled concrete and geosynthetic aggregates. Aggregate may be natural, manufactured or recycled. • Aggregates make up some 60 -80% of the concrete mix. They provide

Contact

stone aggregate plant process

stone aggregate plant process. stone aggregate plant process vakantiebijbelclubommen Construction Aggregate Crushing Plant Construction aggregate, or simply "aggregate", is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates.

Contact

stone aggregate plant process schaut-doch-mal.de

Jun 16, 2014 The U.S. Geological Survey (USGS) defines the construction aggregates industry as those companies that mine and process crushed stone and construction sand and gravel. The construction aggregates industry is active in all 50 states and consists of about 5,400 mining companies that manage more than 10,000 operations.

Contact

stone aggregate plant process

Building Stone Making Plant Process Cement, Aggregate with High Efficient Cement, aggregate and rocks all belong to the building stones. It needs crushing and grinding making plant to process these large scale materials into the production requirements size.Aggregate Quality Control and Process Information Management System StonemontQC is the

Contact

Manufactured Sand and Crushed Stone Aggregate

The designed processing capacity of the coarse crushing area is 1500t/h, and the pebbles of the foundation pit are transported to the raw material warehouse and the grate silo for processing by dumping and trucking. Aggregate larger than 300mm enters the jaw crusher for crushing, equipped with a F5X1045 vibrating feeder and a PEW760 jaw crusher.

Contact

production process of aggregates MiningQuarry Plant

Mar 12, 2013Aggregate Production Process. Aggregate crushing plant mainly by vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centrally electric Aggregate Rock Production Process Coarse aggregate and fine aggregate production equipment The common coarse aggregate are gravel and pebble.

Contact

11.19.1 Sand And Gravel Processing US EPA

11/95 Sand And Gravel Processing 11.19.1-1 11.19.1 Sand And Gravel Processing 11.19.1.1 Process Description1-6 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in near-surface alluvial deposits and in subterranean and subaqueous beds.

Contact

Building Stone Making Plant Process Cement, Aggregate

Primary processing plant of the whole making plant refers to the stone rocks crushing plant. This making stage consists of jaw crusher, sand making machine, vibrating screen, sand washing machine and belt conveyor.

Contact

Lime Stone Aggregate Briquette Process In Rwanda

stone crushing plant workig process The operation procedure is reasonable first raw material is crushed by jaw crusher it is called coarse crushing then the coarse aggregate is conveyed to the impact crusher by conveyor belt to be crushed again

Contact

Aggregate Production Process Cornerstone Aggregates Inc.

Aggregate Production Process. Our Crushing Plant is now considered the most reliable plant in CALABARZON, specifically Batangas. The plant is located at Brgy. Lucsuhin, Calatagan, Batangas, Philippines. QUARRYING. This is an essentials stage in the production process, because the quality of the aggregates produced depends on it. This is our

Contact

Stone Aggregate Plant Process

building stone making plant process cement aggregate with. Key points. • 'Aggregate' is a term for any particulate material. It includes gravel, crushed stone, sand, slag, recycled concrete and geosynthetic aggregates. Aggregate may be natural, manufactured or recycled. • Aggregates make up some 60 -80% of the concrete mix. They provide

Contact

stone aggregate plant process schaut-doch-mal.de

Jun 16, 2014 The U.S. Geological Survey (USGS) defines the construction aggregates industry as those companies that mine and process crushed stone and construction sand and gravel. The construction aggregates industry is active in all 50 states and consists of about 5,400 mining companies that manage more than 10,000 operations.

Contact

stone aggregate plant process

Building Stone Making Plant Process Cement, Aggregate with High Efficient Cement, aggregate and rocks all belong to the building stones. It needs crushing and grinding making plant to process these large scale materials into the production requirements size.Aggregate Quality Control and Process Information Management System StonemontQC is the

Contact

Manufactured Sand and Crushed Stone Aggregate Processing

The sand-making area has a processing capacity of 1500t/h, equipped with 3 VSI6X1263 vertical shaft impact crushers with a processing capacity of 500t/h. After the 0-31.5mm semi-finished product is passed, shaped and powdered, qualified machine-made sand and fine crushed stone will be formed. The 0-31.5 mm material produced by the cone crusher

Contact

Sand and Gravel Aggregate Process Plant Camelway Machinery

The fine aggregates with a particle size below 5mm is also called sand whereas the particle size above 5mm is called coarse aggregate, which is known as a stone. Camelway has years of experience in producing sand and gravel aggregate equipment. At the same time, our crushing plants provide high-quality sand and gravel aggregates for many projects.

Contact

What is Stone Aggregate? What are Chips and Pebbles? DIY

Aggregates (also commonly referred to as chips and pebbles or crushed stone in the industry) are a particular material made up of crushed stone, sand, or gravel. There are a variety of sizes available depending on the specific application. Some types (like our popular Mexican Beach Pebbles) can measure as large as two to three inches in diameter.

Contact

Building Stone Making Plant Process Cement, Aggregate with

Aggregates making plant for coarse and fine aggregate processing; High fineness and low energy bentonite grinding mill widely used; Efficient Brick Crusher for Sale; Building Stone Making Plant Process Cement, Aggregate with High Efficient; PEW Series Jaw Crusher Used in the Ceramics Processing Line; Well Known Concrete Product Line is Popular

Contact

Crushed Stone Aggregates Lehigh Hanson, Inc.

Coarse. Coarse aggregates consist of gravel, crushed stone or recycled concrete with particle sizes of ranging from 3/8-inch to 1.5 inches. Coarse aggregates are used in a wide range of construction applications, notably in concrete and asphalt mixes. Common uses for coarse crushed stone. • Concrete aggregate.

Contact

The Complete Guide to Crushed Stone and Gravel gra-rock

Nov 11, 2019Like crushed stone, gravel can be used as an aggregate for pavement, ready mix concrete, or other construction applications. Best applications for crushed stone We have already referenced many places where crushed stone is used, but the most common are construction projects that need concrete, solid bases, or drainage systems.

Contact

stone aggregate plant process

Aggregate stone crushing plant,Aggregate stone crushing, Aggregate crushing plants may be fixed or mobile. The designed Aggregate crushing plants capacity is from 50t/h to 1000t/h. Go to Product Center. stone aggregate plant process Ore Machine China, stone aggregate plant process .

Contact

What You Need To Know About The Aggregate Crushing Plant

Sep 01, 2020August 27, 2020. thef. The aggregate crushing plant is used by many industries in various production processes of specific raw materials. These crushing plants use different equipment, like a pre-screener, magnetic separator, loading conveyor, and crushing units, such as cone crushers and jaw crushers. Aggregate Crushing Plants.

Contact

flow chart of three stage agreegate crushing plant GodSend

Oct 21, 2020flow chart of of aggregate crushing plant. Flow chart of three stage agreegate crushing plant. Oct 11, 2013 Jaw crusher is the major crushing equipment in aggregate plant. The technology of three crushing stages, with jaw, cone, impactor, VSI crushers, makes it possible to produce Process Flow Chart Of Aggregate Plant. get price. Get A Quote

Contact

aggregate mixing plant primary jaw crusher stone

aggregate mixing plant, aggregate mixing plant Suppliers and. Alibaba offers 314 aggregate mixing plant products. About 231% of these are Asphalt Mixers, 355% are Concrete Batching Plant, and 2% are Dry Mortar Machines. A wide variety of aggregate mixing plant options are available to you, Compact dosing and mixing plant

Contact

stone aggregate plant process

Aggregate stone crushing plant,Aggregate stone crushing, Aggregate crushing plants may be fixed or mobile. The designed Aggregate crushing plants capacity is from 50t/h to 1000t/h. Go to Product Center. stone aggregate plant process Ore Machine China, stone aggregate plant process .

Contact

stone aggregate plant process

stone aggregate plant process. stone aggregate plant process vakantiebijbelclubommen Construction Aggregate Crushing Plant Construction aggregate, or simply "aggregate", is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates.

Contact

Aggregate Processing Plant Design LZZG

Vibrating feeder is commonly used to delivery raw materials to the crushers and vibrating screening equipment in the gravel aggregate processing plant. And sort and remove the debris in it to facilitate the next processing procedure. In the gravel aggregate processing line, the vibration feeder equipment is generally used to supply the stone. 2.

Contact

Stone Aggregate Plant Process

Stone Aggregate Plant Process. aggregate washing plant for aggregate process,december.03,2020. sand and gravel aggregate cleaning equipment the cleaning of stone mainly refers to the removal of clay or clay substances in gravel or

Contact

Stone Aggregate Plant Process

Stone Crusher Plant How to Start Business Project Plan. Stone Crusher Plant Production Process. First of all, break the big stone boulders to smaller size manually. Then it is fed to the stone crusher. The crusher can accept the stone size of 175mm. Stone crushing is the two-stage process. In the first. stage, crush the 175mm stone to about 50mm.

Contact

Aggregate Crushing Plant How to Run a Crushing Plant JXSC

Improving the productivity of aggregate processing plant, which on the sand aggregate manufacturing process put forward higher requirements. 1 Aggregate processing plant design 1.1 Crusher. How many times a raw stone be crushed to produce the finished aggregate? As we all know, the higher the crushing times, the higher the cost.

Contact

Crushed Stone Aggregates Lehigh Hanson, Inc.

Coarse. Coarse aggregates consist of gravel, crushed stone or recycled concrete with particle sizes of ranging from 3/8-inch to 1.5 inches. Coarse aggregates are used in a wide range of construction applications, notably in concrete and asphalt mixes. Common uses for coarse crushed stone. • Concrete aggregate.

Contact

What You Need To Know About The Aggregate Crushing Plant

Sep 01, 2020August 27, 2020. thef. The aggregate crushing plant is used by many industries in various production processes of specific raw materials. These crushing plants use different equipment, like a pre-screener, magnetic separator, loading conveyor, and crushing units, such as cone crushers and jaw crushers. Aggregate Crushing Plants.

Contact

Aggregate Stockpiling and Handling

The 3 step process- Really? 25 plant customer stone) •Do not cast over the side, this promotes segregation •If ramping unavoidable, load ramped material for commercial uses (under slab, drainage fill, etc) 36 • Changes in the aggregate properties will cause changes

Contact

aggregate mixing plant primary jaw crusher stone

aggregate mixing plant, aggregate mixing plant Suppliers and. Alibaba offers 314 aggregate mixing plant products. About 231% of these are Asphalt Mixers, 355% are Concrete Batching Plant, and 2% are Dry Mortar Machines. A wide variety of aggregate mixing plant options are available to you, Compact dosing and mixing plant

Contact

Aggregate Crushing Plant and Processing Sand Maker

1 Basic information about the aggregate production line. 1) Capacity: 1 000 t/h gravel aggregate. 2) Product variety: 0.075~4.75 mm, 4.75~15 mm, 15~31.5 mm gravel aggregate. 3) Characteristics of raw materials: The limestone and clay content are large. 4) The quality of gravel aggregate meets the requirements of GB/T 14685-2011 “Construction

Contact

flow chart of three stage agreegate crushing plant GodSend

Oct 21, 2020flow chart of of aggregate crushing plant. Flow chart of three stage agreegate crushing plant. Oct 11, 2013 Jaw crusher is the major crushing equipment in aggregate plant. The technology of three crushing stages, with jaw, cone, impactor, VSI crushers, makes it possible to produce Process Flow Chart Of Aggregate Plant. get price. Get A Quote

Contact

Home Memphis Stone and Gravel

From stonegravel supply to highway paving, Roberts Family Companies provide high-quality services across the Mid-South. Consisting of Memphis Stone and Gravel and sister company Lehman-Roberts, we’re known for our remarkable work — and as a business, we constantly work to provide an environment every team member is proud to call home

Contact

batching plant process flow chart electric portable jzc750 mini stone

ECA Self-movable mobile plant. 30 to 120 m 3 /h; EBA Mobile plant for medium productions. 30 to 70m 3 /h; EMA Compact plant, perfect for prefabricated. From 30 to 100 m 3 /h; MODULMIX Plant for large productions and special concretes. 80 to 150 m 3 /h; FASTMIX Mini plant.12 to 19 m 3 /h; Dry mix.

Contact