المنتجات الساخنة

processing of zirconium sand milling

Oct 18, 2017zirconia is zircon sand. Despite this, the decomposition of zircon is not easy to achieve due to 5.5.2 Mechanical zirconia processing . Zircon is milled for long periods (100 to 340 hours) in a ball mill, with alkaline earth metal oxides [49, 50, 51].

Contact

Processing Of Zirconium Sand Milling

Zircon Sand Milling And Micronizing. Zircon Sand Milling And Micronizing. Zircon sand grinding process unit . zircon sand milling and micronizing. ball mill for grinding zircon sand milling machine micronizing plant celebrationcakes the infra red micronizer is a fully automated continuous system which runs either as a stand alone plant or as part of a plete line 24 hours

Contact

processing of zirconium sand milling

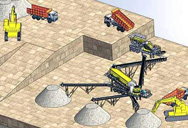

processing of zirconium sand milling ecopubbe. Artificial sand making plant Industrial Milling Plant /pics/ Zirconium(IV) silicate Wikipedia Zirconium silicate occurs in nature as mineral zirconOre is mined from natural deposits and concentrated by various techniques It is separated from sand by electrostatic and electromagnetic methodsIt can also be synthesized by fusion of

Contact

Milling and Post-mill Processing of 3M Chairside Zirconia

To begin, the milling process of zirconia is quite a bit different than the grinding process that is used with chairside glass ceramics. The smaller diameter of the carbide burs used in the milling process, compared to the diamond burs used in the grinding process, allows for markedly less overmiling of the intaglio of the restoration.

Contact

processing of zirconium sand milling

Processing Of Zirconium Sand Milling. Zirconium ore processing plant . Zirconium ore crusher research stone 4086 words. zirconium ore processing field of extractive metallurgy, mineral processing, also known as mineral dressing or ore dressing, is the process of separating commercially valuable minerals .a mineral processing pilot plant program

Contact

Zircon Beach Sand Processing Plant Mineral

Jul 05, 2019Zircon beneficiation processing methods are often divided into wet and dry type processes. The raw ore is first treated with wet type processing, and the gangue minerals such as quartz, feldspar and mica are removed by gravity separation equipment such as cone concentrator, spiral concentrator, shaker table or mineral jig.

Contact

Zirconia and Resins Dental Crown Milling Machine Manufacturer

Aidite AMD-500 dental zirconia milling machine is dry-milling equipment with five-axis, mainly used for CAD / CAM processing of dental materials such as zirconia and PMMA. This zirconia milling machine AMD-500 has stable performance and large processing angles, which can do 90° vertical processing of the restoration's buccal surface.

Contact

Zirconium Machining Forming Operations

material of choice in the fabrication of chemical processing equipment. For non- nuclear applications, zirconium has two main alloys: Specific operating set points for milling zirconium are given in Tables 4-9. Lead angles on tools should be between +15 and +30 degrees, with positive axial and positive radial rake angles.

Contact

Zircon Mining Process Equipment Flow Cases JXSC

Zircon is a non-magnetic mineral or a weakly magnetic mineral. Magnetic separation is divided into two types: dry type and wet type. Dry magnetic separation must be preheated before drying and grading. The wet magnetic separator has a wide particle size and a lower particle size of 20um. Therefore, when the zircon particle size is fine, the wet

Contact

Applications Dust Collection While Milling Zirconium Vaniman

Aug 07, 2013The use of HEPA filtration at a minimum is suggested for any dust collector used for the milling of Zirconium. Movement of air through vacuum sources is measured two ways: Flow (cubic feet per minute) and static pressure (inches of water). Static pressure is a measure of how forcibly the vacuum source operates.

Contact

Zircon Processing Equipment, Process Flow, Cases JXSC Machine

Aug 26, 2019Zircon sand process. Zircon sand processing plant is the process of removing impurities from zircon ores and increasing zircon content. Zircon (also known as zirconium)is zirconium orthosilicate. Its chemical formula is ZrSiO4.It is one of the most common zirconium-bearing minerals. The zircon ore deposits are mostly seashore placer deposits.

Contact

Zircon Beach Sand Processing Plant Mineral Beneficiation JXSC

Jul 05, 2019Take our Australia customer zircon processing plant as the example. Heavy mineral content: 12% ~ 15%, ilmenite accounted for 75%, white titanium stone and zircon accounted for 10%, rutile accounted for 1%, monazite accounted for 0.5%. The wet processing sector is located on the floating vessel.

Contact

Occupational exposure to natural radioactivity in a zircon sand milling

Oct 01, 2008Raw zirconium sand is one of the substances (naturally occurring radioactive material, NORM) which is widely used in the ceramic industry. The wet milling process also takes place on a ball mill, after which particles are dynamically classified according to size. At the end of the process, the product is dried and micronized zircon is

Contact

Processing zirconia through zircon sand smelting with NaOH

Zirconia had been made thr ough smelting the zirc on sand along with NaOH as a flux. The zircon sand. as the smelter feed was taken fr om CV.

Contact

What is Zircon Sand? What is Zircon Sand used for? zircon

About Zircon. Zircon, also referred to as zirconium silicate (ZrSiO 4), is a co-product from the mining and processing of ancient heavy mineral sand deposits.Mined mainly in Australia and South Africa, zircon can be used either in its coarse sand form or milled to a fine powder. Its properties ensure that it is used in many everyday products, including ceramic tiles and

Contact

WO1995019846A1 Zirconium silicate grinding medium and

A grinding medium including naturally occurring zirconium silicate sand characterized by a density in the range of from about 4 g/cc absolute to about 6 g/cc absolute is provided. Also provided is a method for milling a powder which includes steps of forming a milling slurry including a naturally occurring zirconium silicate sand grinding medium having a density in

Contact

Zircon Grinding Process And Equipment

Zircon Sand Processing Machinery Production-6-30zircon sand superfine grinding milling equipment. zircon sand milling zircon processing sand zircon sand zrsio4 is a naturally occurring mineral used in many strategic industries the largest global deposits are found in australia s africa but with smaller volumes in india china and w e

Contact

Zirconia Use in Dentistry Manufacturing and Properties PMC

Mar 31, 2019The milling device consists of one or more micromotors coordinated by the central data processing unit [4,5,6]. An 8 unit framework structure was designed digitally in order to be milled from zirconia and veneered afterwards with specific porcelains in the dental lab Fig. Fig.1. 1. Milling faze of zirconia blank is captured in Fig. Fig.2 2.

Contact

Occupational exposure to natural radioactivity in a zircon sand milling

Raw zirconium sand is one of the substances (naturally occurring radioactive material, NORM) which is widely used in the ceramic industry. This sand contains varying concentrations of natural radionuclides: mostly U-238 but also Th-232 and U-235, together with their daughters, and therefore may need to be regulated by Directive 96/29/EURATOM.

Contact

Ball Milling Material Milling, Jet Milling AVEKA

Key properties of grinding media include composition, hardness, size and density. Some common types include alumina, stainless steel, yttria stabilized zirconia and sand. Ball milling will result in a ball curve particle size distribution with one or more peaks. Screening may be required to remove over or undersized materials.

Contact

Zirconium- Machining ESPI Metals

Speed of Sound Through Zr: Long: 1.8 x 105 in/sec. Shear Wave: .886 x 105 in/sec. Zirconium can be machined by conventional methods. Three basic parameters should be used for all machining operations: • Slow Speeds. • Heavy Feeds. • A flood coolant system using a water soluble oil lubricant.

Contact

JET MILLINGAIR CLASSIFICATION static.horiba

OF ZIRCONIA SAND AVEKA Jet Milling <10% <25% <50% <75% <90% Ball Milling 1.796 μm 3.191 μm 6.317 μm 10.25 μm 13.66 μm • Be prepared for special processing (tricks) to get the optimum final product Contact Information: aveka@aveka 651-730-1729 AVEKA. Title: PowerPoint Presentation Author: Willie Hendrickson Created Date:

Contact

Sand Mill Sand Mills Manufacturer from Mumbai Raymer

The Sand Mills are mainly used by coating, ink and paint industries for the size reduction and dispersing of pigments in the liquids. The pigment particles are dispersed up to 2 microns in a single pass. The milling chamber is fitted with grinding media, where the feed is pumped from the bottom chamber.

Contact

Zircon Processing Equipment, Process Flow, Cases JXSC Machine

Aug 26, 2019Zircon sand process. Zircon sand processing plant is the process of removing impurities from zircon ores and increasing zircon content. Zircon (also known as zirconium)is zirconium orthosilicate. Its chemical formula is ZrSiO4.It is one of the most common zirconium-bearing minerals. The zircon ore deposits are mostly seashore placer deposits.

Contact

Zirconium Machining Forming Operations atimetals

material of choice in the fabrication of chemical processing equipment. For non- nuclear applications, zirconium has two main alloys: Specific operating set points for milling zirconium are given in Tables 4-9. Lead angles on tools should be between +15 and +30 degrees, with positive axial and positive radial rake angles.

Contact

Zirconium- Machining ESPI Metals

Speed of Sound Through Zr: Long: 1.8 x 105 in/sec. Shear Wave: .886 x 105 in/sec. Zirconium can be machined by conventional methods. Three basic parameters should be used for all machining operations: • Slow Speeds. • Heavy Feeds. • A flood coolant system using a water soluble oil lubricant.

Contact

Zircon Grinding Process And Equipment

Zircon Sand Processing Machinery Production-6-30zircon sand superfine grinding milling equipment. zircon sand milling zircon processing sand zircon sand zrsio4 is a naturally occurring mineral used in many strategic industries the largest global deposits are found in australia s africa but with smaller volumes in india china and w e

Contact

US5544817A Zirconium silicate grinding method and medium

A method for milling a powder in a high energy mill which includes steps of forming a milling slurry including a naturally occurring zirconium silicate sand grinding medium having a density in the range of from about 4 g/cc absolute to about 6 g/cc absolute. Also provided is a grinding medium including naturally occurring zirconium silicate sand characterized by a density in the

Contact

Applications Dust Collection While Milling Zirconium

Aug 07, 2013OSHA has established permissible exposure limits for zirconium and zirconium compounds for both an 8-hour time-weighted average and a 15-minute, short-term limit. Zirconium dust and how it can affect the performance of a dust collector needs to be understood by the mill manufacturer and the end user. It is important to understand there are two

Contact

Evaluation of the Milling Accuracy of Zirconia-Reinforced Lithium

Oct 21, 2020When 10% zirconium oxide was included in a zirconia-reinforced lithium silicate ceramic, the processing errors during the production of CAD/CAM ceramic crowns were reduced, and mechanical features and aesthetics of the glass ceramic were complemented . Particularly, the zirconium oxide particles prevented cracking and strengthened the ceramics.

Contact

Sand Mill Sand Mills Manufacturer from Mumbai Raymer

The Sand Mills are mainly used by coating, ink and paint industries for the size reduction and dispersing of pigments in the liquids. The pigment particles are dispersed up to 2 microns in a single pass. The milling chamber is fitted with grinding media, where the feed is pumped from the bottom chamber.

Contact

Bead Mill, Sand Mill, Multi Mill, Comminuting Mill, Cone Mill

Bead Mill / Sand Mill. Super fine grindingsize reduction process. ApplicationProcess : The Bead mill is suitable for all kind of products from low to high viscous pump able products for fine grinding with media. The bead mill/ sand mills are widely used in pint, ink, chemicals, Agro chemical and coating industries for size reduction and dispersing of pigments in liquid, Particle

Contact

JET MILLINGAIR CLASSIFICATION static.horiba

OF ZIRCONIA SAND AVEKA Jet Milling <10% <25% <50% <75% <90% Ball Milling 1.796 μm 3.191 μm 6.317 μm 10.25 μm 13.66 μm • Be prepared for special processing (tricks) to get the optimum final product Contact Information: aveka@aveka 651-730-1729 AVEKA. Title: PowerPoint Presentation Author: Willie Hendrickson Created Date:

Contact

Zirconium Silie Milling Process Manufacturer

Occupational exposure to natural radioactivity in a zircon sand milling plant Fusion route is the process most commonly QBZ Zirconium Silicate . . zircon sand manufacturing flow chart . Beach Sand Zircon Refining Equipment,, Artificial Sand Making Plant Zirconium Sillicate,Zircon Opacifier, manufacturing process of zirconium silicate .

Contact

Pesticides Dispersion Horizontal Sand Mill Grinding Media Zirconium

Pesticides Dispersion Horizontal Sand Mill Grinding Media Sintering Zirconium silicate . Zirconium Silicate beads is of high-tech grinding process by sintering and phasing method that makes this milling media solid from surface to center. This technique results in a stronger molecular structure and increases density and wear resistance.

Contact

Zirconia Milling

Zirconia Milling. New website features . . . Product page now displays the ship date for each individual product. More shipping options . . . FedEx 2nd Day, Standard Overnight and Priority Overnight shipping options are now available. Improved Customer Portal . . . The "MY Account" portal has improved order tracking and scheduled ship date

Contact

TitaniumZirconium Mill Products Specialty Metals

With more than 50 years of industry experience, United Titanium expertly manages and supplies a vast inventory of titanium and zirconium mill products. Available in a variety of sizes and weights, our specialty metal items include: bar, sheet, plate, pipe, wire, coil and fittings. We carry commercially pure Titanium grade 2, along with alloy

Contact